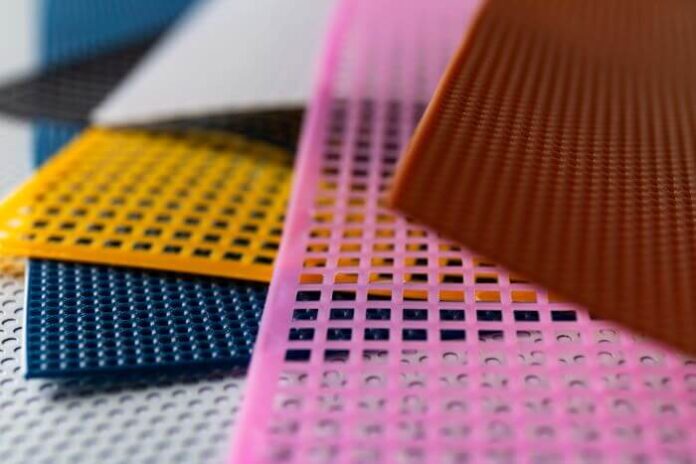

Perhaps you have also heard about polypropylene fabric and have been longing to know about it. Well, polypropylene fabric is a versatile material that is used extensively in a wide range of industries due to the various properties that make it highly suitable for different applications.

The fabric is made from a thermoplastic polymer known as polypropylene, which is extremely strong and durable. A material made from polypropylene fibers is lightweight, water-resistant, chemical-resistant, and abrasion-resistant.

The material is widely used in the automotive, medical, and packaging industries, as it has various properties that make it a popular choice for industrial applications. For instance, the automotive industry uses polypropylene fabric for car interiors, as it is known for its durability, resilience, and versatility.

Medical textiles are also often made from polypropylene fabric due to its non-woven nature, which makes it easy to sterilize and dispose of.

In this blog post, we will take a closer look at fabric backed polypropylene sheets and explore their many industrial applications. We will also look at the environmental concerns surrounding these sheets and discuss some potential solutions.

Some Industrial Applications of Polypropylene Fabric

1. Applications in the automotive industry

Polypropylene fabric has become a popular material for use in car interiors due to its superior properties and durability. This material is used in many automotive components such as seats, headrests, door trim, and carpets.

One of the main advantages of polypropylene fabric is that it is highly resistant to spills and stains, making it perfect for use in car interiors where it is exposed to various liquids and chemicals. Furthermore, polypropylene fabric is breathable, which provides for better air circulation and moisture management inside the car.

Also, polypropylene fabric is much more affordable than other materials, such as leather. Therefore, it is a popular choice for mass-production vehicles. Because of these unique characteristics, polypropylene fabric continues to be a highly sought-after material in the automotive industry.

2. Applications in the medical industry

Polypropylene fabric has also been widely adopted by the medical industry for its exceptional properties and benefits. Medical textiles made from polypropylene fabric are nonwoven, which allows for disposable and easy-to-sterilize materials to be produced. Because it can be easily sterilized, it is often used for the production of clothing and coverings such as face masks, gowns, caps, and shoe covers.

Polypropylene fabric is also hydrophobic, which means that liquids cannot penetrate it. This helps keep medical professionals safe from contamination and transmission of diseases. At the same time, medical textiles made from polypropylene are lightweight, making it easier for doctors and nurses to move around and work with patients.

3. Applications in the packaging industry

Apart from the automotive and medical industries, polypropylene fabric is also widely used in the manufacturing of packaging materials due to its durability, flexibility, and versatility. It is often used to produce sacks, bags, and other containers for various items ranging from food products to chemicals.

Polypropylene fabric is ideal for packaging materials as it is resistant to moisture and chemicals. So it is a perfect option for packaging products that are sensitive to the environment or that require airtight packaging.

The fabric is also resistant to tearing and can withstand high levels of stress, making it ideal for bulk storage and transportation. And because it is lightweight, it helps to reduce shipping costs and carbon emissions when compared to other packaging materials.

3. Environmental impact of polypropylene fabric

With all these amazing benefits of using polypropylene fabric across several industries, it also has its own unique challenges that need to be addressed. The material has several environmental concerns that should be taken care of to ensure that its use remains sustainable and environmentally friendly.

One of them is the use of nonrenewable resources to manufacture polypropylene fabric. Also, the manufacturing process produces a high level of greenhouse gases, contributing to climate change. There is also the issue of waste generated from discarded fabrics.

Some manufacturers are finding ways to mitigate these issues through an eco-friendly approach to production, such as using renewable energy sources, reducing waste production, and recycling post-consumer waste.

Furthermore, alternatives to traditional polypropylene fabric manufacturing practices are also being developed, such as eco-friendly fibers derived from renewable sources. Adopting these alternative practices, along with recycling and reusing materials, offers promising solutions to the environmental impact associated with polypropylene fabric production and use.

Final Note

A variety of industries, including automotive, medical, and packaging, have found widespread use for polypropylene fabric because of its different unique properties. We have already mentioned some of them in this article, including their versatility, durability, and affordability.

As more attention is paid to environmental concerns in the manufacturing industry, the production of polypropylene fabric is also moving toward sustainable practices, highlighting its adaptability.

And to address some challenges that come with the material, the adoption of new technologies such as eco-friendly fibers derived from renewable sources and biodegradable fabrics that break down naturally upon disposal also holds great promise.

With this, polypropylene fabric will not only be durable and versatile but a sustainable choice for a wide range of industrial applications, minimizing waste and maximizing efficiency and productivity.