Plastics are everywhere you look. From the water bottle in your hand to the keyboard you’re typing on, these versatile materials have become an undeniable part of this modern world. But have you ever stopped to consider the impact of all this plastic?

Estimates suggest that the world creates over 400 million tons of plastic waste every year, indicating a booming production. While plastics offer undeniable benefits – think lightweight packaging and medical applications – growing mountains of waste and environmental concerns are casting a long shadow over this industry.

So, if you’re an entrepreneur with an eye on the future, the question becomes: is there a way to innovate and be part of the solution? Buckle up because the landscape of plastic manufacturing is undergoing a fascinating transformation, and this article will equip you with the knowledge to navigate it.

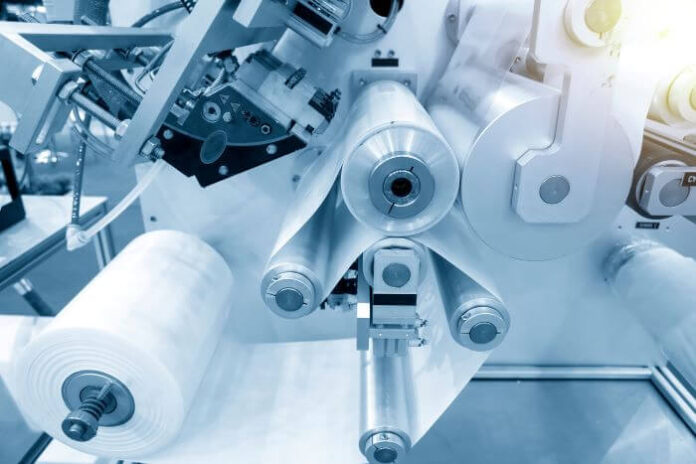

Even for established businesses utilizing traditional methods like the plastic injection molding machine, the winds of change are undeniable. New technologies and a focus on sustainability are reshaping this industry, opening doors for fresh ideas and opportunities.

1. Bioplastics

Traditionally, plastics are derived from fossil fuels, raising concerns about resource depletion and environmental impact. Bioplastics offer a glimmer of hope, promising a more sustainable alternative. Scientists create these innovative materials from renewable biomass sources like plant starches, vegetable oils, or even bacteria.

There are two main categories of bioplastics:

- Bio-based plastics: These are derived from biological sources but might not necessarily be biodegradable. Polylactic Acid (PLA), for example, is a standard bio-based plastic made from fermented corn starch. It’s often used for disposable cutlery, cups, and even clothing because it performs well and can be processed using existing plastic injection molding machines.

- Biodegradable plastics: These not only come from renewable resources but also break down naturally under the right conditions, typically in industrial composting facilities. Polyhydroxyalkanoates (PHAs) are a prime example. Produced by microorganisms when fed sugars or starches

Bioplastics aren’t a silver bullet, though. Production costs can be higher compared to traditional plastics, and their performance characteristics might vary. However, the bioplastics industry is rapidly evolving. Scientists are constantly researching new materials and refining production processes to bring down costs and improve performance. As consumer demand for sustainable alternatives grows, bioplastics are poised to play a significant role in the future of plastic manufacturing.

2. 3D Printing and Additive Manufacturing

Imagine a world where you can design and create custom plastic parts on-demand, all from the comfort of your home or office. These technologies are fundamentally changing how industries think about plastic production, offering several advantages for entrepreneurs:

- Customization: 3D printing allows for highly customized plastic parts. This technology opens doors for creating unique prototypes, low-volume production runs, and even personalized end-use products.

- Reduced waste: Traditional manufacturing often generates significant scrap plastic. 3D printing, however, uses a more additive approach, building the object layer by layer with minimal material waste.

- On-demand manufacturing: 3D printing empowers businesses to produce parts locally, eliminating the need for large stockpiles or dependence on overseas manufacturing.

Of course, 3D printing for plastic also has limitations. Production speed can be slower compared to traditional methods, and the range of materials available for 3D printing might not yet encompass all the properties needed for every application.

However, the potential of 3D printing is undeniable. As technology advances and printing speeds increase, the world can expect to see this technology play a significant role in the future of plastic manufacturing, particularly for complex, customized parts and low-volume production runs.

3. The Circular Economy for Plastics

The traditional “take-make-dispose” model of plastic production isn’t sustainable. The circular economy offers a refreshing alternative, focusing on keeping plastics in use for as long as possible. Here, the emphasis is on:

- Reduce: Designing products that minimize plastic usage in the first place.

- Reuse: Encouraging the reuse of plastic items whenever possible, like refillable water bottles or reusable shopping bags.

- Recycle: Developing and implementing efficient recycling technologies to transform plastic waste back into usable materials.

The circular economy isn’t just about environmental benefits. It can also create new business opportunities, like recycling plants specializing in plastic or innovative refill systems for everyday products.

4. Smart Plastics and New Materials

Plastic is no longer just about rigidity and lightweight packaging. The world of “smart plastics” is emerging, introducing a new generation of materials that push the boundaries of what plastic can be. These innovative materials are embedded with functionalities that respond to external stimuli, opening doors for exciting applications:

- Self-healing plastics: Consider a phone case that can mend minor scratches on its own. Researchers are developing polymers that repair themselves when exposed to light or heat, potentially reducing the need for frequent replacements.

- Biodegradable plastics with enhanced functionality: This could be a game-changer for applications like medical implants or agricultural films. Imagine a bioplastic that degrades naturally after serving its purpose, eliminating microplastic pollution concerns.

- Shape-shifting plastics: Scientists are exploring materials that can change their shape in response to temperature or pressure. Manufacturers could use these in products like self-deploying shelters or even clothing that adapts to different weather conditions.

- Chromatic plastics: These innovative materials change color in response to specific environmental factors, like temperature or UV exposure. Picture a milk bottle that turns opaque when the milk spoils or a food container that indicates internal temperature for safety.

- Conductive plastics: Envision integrating electronic components directly into plastic packaging. This type could revolutionize areas like smart packaging that tracks freshness or monitors product tampering.

The development of smart plastics is still in its early stages, but the potential is vast. Entrepreneurs who can identify market needs and leverage these new materials can develop innovative products and disrupt established industries.

Final Thoughts

The message is clear: innovation and sustainability are no longer afterthoughts; they’re the driving forces. This landscape presents a wealth of opportunities for entrepreneurs with a vision. Are you ready to be a part of this transformation? The time to act is now. Dive deeper into these trends, identify a niche, and unleash your creativity. The future of plastic awaits shaping.